Description:

INSTANUTE IR is a “ready to use” coating system to be reconstituted in water, consisting of Hydroxypropylmethylcellulose (HPMC), specific for nutritional applications. It is available in a wide range of colors, both of natural and synthetic origin, and can also include flavors.

HPMC is one of the most used polymers for filming coating. It dissolves in cold water, forming a colloidal solution. It can be applied in formulations intended for use in equipment of different designs and sizes.

Benefits:

Reconstitution level:

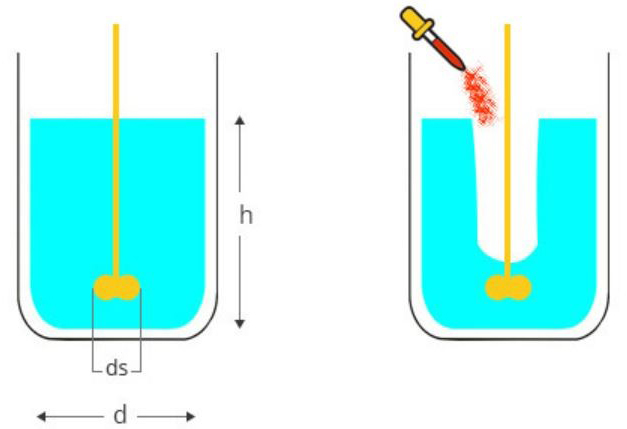

Reconstitution in purified water up to 12% w/w of solid

Recommended equipment:

Mechanical stirrer with variable speed

Mixing Vessel

Calculation for the quantities of INSTANUTE IR and solvent:

The amount of INSTANUTE IR (12% w/w) and water required is based on the amount of cores that need to be coated and the desired weight gain. For 1 kg of nuclei and a 3% weight gain, 30 g of INSTANUTE IR will be required to be added to 250 g of water kept under stirring.

Reconstitution process:

Gli uffici IPDistribution srl resteranno chiusi per le festività natalizie

dal 27 al 29 dicembre 2023, compresi

IPDistribution offices will remain closed for Xmas break

during December 27th to 29th, 2023 included